From the bamboo cable percussion drilling of the Zhuotong Wells in the Northern Song Dynasty to the kilometer-deep drilling of the Shenhai Well in Zigong; from the gush of black gold at Spindletop in Texas to the 10,000-meter breakthrough in the Taklamakan Desert—each advancement in drilling technology represents humanity deciphering the Earth's deep secrets. This millennia-long technological Long March of drilling not only measures geological depths but also charts the breadth of human civilization.

In this issue, we review the development of drilling engineering, a crucial link in the exploitation of oil and gas resources.

Shenhai Well Old Salt Field

I. Decoding Classic Technologies: The Evolution from "Percussion" to "Navigation"

Percussion Drilling: The Primitive Yet Ingenious "Subterranean Knock"

Percussion drilling (also known as cable-tool drilling) is the earliest drilling technology, originating in Zigong, Sichuan, and traceable back to the Eastern Han Dynasty.

A wooden frame, leveraging the principle of a lever, drove a heavy iron bit (weighing hundreds of jin) to strike the formation at a frequency of 10-20 times per minute. Combined with bailing out cuttings using a bamboo tube, this "percussive strike and bailing" cycle extracted underground resources like oil, natural gas, and brine from the wellbore.

Schematic Diagram of Percussion Cable-Tool Drilling Technology

The pinnacle of this traditional technology was the Shenhai Well, completed in Zigong, Sichuan, in 1835. Through innovations like using wear-resistant alloy bits, optimizing power transmission with ox-powered winches, and pioneering well deviation measurement and correction techniques for precise control, the Shenhai Well successfully penetrated the Triassic Jialingjiang Formation. Achieving a depth of 1001.42 meters, it became the "world's first artificially drilled kilometer-deep well," simultaneously producing 14 tons of salt and 8500 cubic meters of natural gas per day.

Twenty-four years later, the Drake Well in the US reached only 21.69 meters, demonstrating the Shenhai Well's far superior technology and depth compared to its Western contemporaries. It remains a key reference point for the industry tracing the "civilization of drilling." Consequently, Joseph Needham hailed percussion drilling as "China’s fifth great invention" and included it in "Science and Civilization in China," acknowledging its profound influence on modern drilling technology.

Rotary Drilling: The "Underground Whirlwind" of the Industrial Revolution

The rotary rig used at the Spindletop oil field in the USA in 1901 completely revolutionized drilling methods, becoming the groundbreaking technology that replaced percussion drilling.

The core of rotary drilling lies in its continuous operation mode of "rotary rock breaking + circulating cuttings removal." The top drive assembly acts like an "underground gyroscope," steadily rotating the drill string 360 degrees. Paired with the drill bit and mud circulation system, it can penetrate tens of meters per hour into the formation, boasting efficiency dozens of times greater than percussion drilling.

The mud circulation system is key to the high efficiency of rotary drilling. Specialized mud (density 1.15-2.4 g/cm³, often called the "lifeblood of drilling") is pumped down the drill pipe, ejected through nozzles in the bit as high-speed jets, and then carries cuttings back to the surface through the annulus (the space between the drill pipe and the wellbore).

This single circulation loop accomplishes multiple tasks: assisting in rock breaking, cooling the hot bit, acting like a "courier" bringing cuttings to surface, maintaining hydrostatic pressure balance to prevent blowouts, and forming a filter cake on the wellbore wall to stabilize the formation.

In 1974, the Bertha Rogers hole in the USA, using this technology, broke through to a depth of 9583 meters, extending human exploration capability to nearly ten thousand meters underground for the first time and opening the door to deep oil and gas development.

Based on how the bit is driven, rotary drilling can be divided into downhole motor drilling and surface drive drilling. The most common surface drive drilling is further divided into conventional rotary table drilling and top drive drilling (TDS).

Rotary table drilling uses a surface rotary table to turn the entire drill string and bit. It's simple in structure, technologically mature, and suitable for medium-to-shallow wells under 5000 meters. Top drive drilling has its power unit installed atop the derrick, directly rotating the drill string from the top. It eliminates the rotary table, avoids rotating the entire string, reduces friction, and further improves drilling efficiency.

To enhance quality and efficiency, more companies are upgrading their conventional rotary table rigs to top drive systems. In September of this year, during drilling operations on a conventional oil and gas well in Block 8 of the Xinjiang Oilfield, Beiken Energy achieved a first within the Xinjiang Oilfield area by installing a top drive on a truck-mounted rig to boost drilling efficiency.

Compared to rotary table drilling, the top drive system reduces operational steps, saves time, and enhances the ability to prevent and handle complex situations. With the top drive, Beiken Energy set a new drilling record for that block with this well.

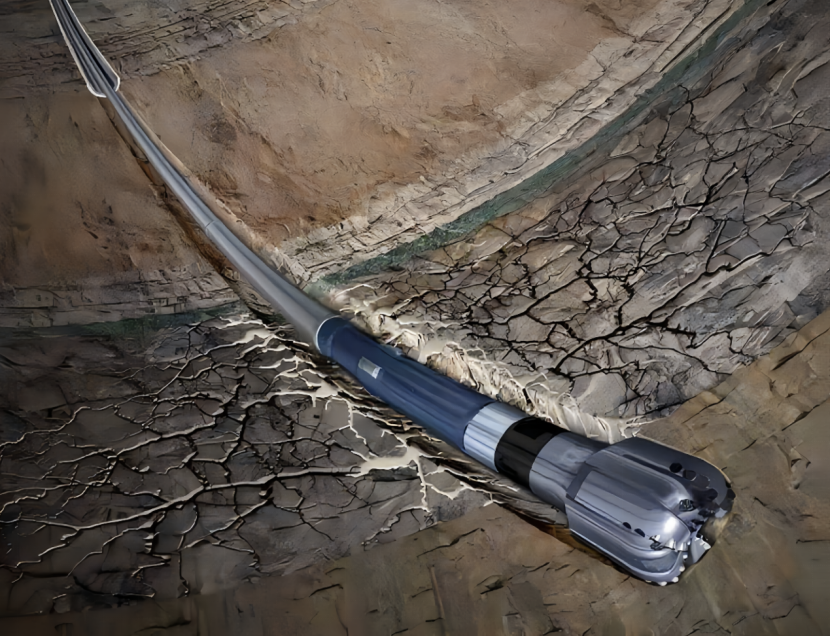

Directional and Horizontal Drilling: The "Precision Navigation Upgrade" of Rotary Technology

After rotary drilling broke the 10,000-meter depth barrier, new challenges emerged: underground oil and gas reservoirs are often like scattered pearls, located in non-vertical formations, such as shale gas and tight gas.

Directional drilling technology, first applied at the Huntington Beach oil field in the USA in 1932, became the "precision extension" of rotary drilling. A horizontal well is a specific type of directional well: when the wellbore inclination reaches or exceeds 90 degrees and extends horizontally within the hydrocarbon-bearing zone, it becomes a horizontal well, achieving the effect of "one well on the surface, a horizontal path underground."

Its core is the "dynamic steering + real-time positioning" system: The "bent sub" or bent housing on a downhole motor acts like an "underground steering knuckle," allowing fine adjustments to the drilling angle. Measurement While Drilling (MWD) tools function like "underground GPS," using gamma rays to determine lithology and resistivity to identify hydrocarbons, transmitting data to the surface in real-time to ensure the bit follows the pre-designed trajectory.

Compared to the vertical thrust of rotary drilling, the horizontal section of a directional well can extend for kilometers through the pay zone like an "earthworm," increasing the contact area between the single well and the reservoir by tens of times, significantly enhancing recovery rates. This "surgical strike" not only reduces surface footprint but also enables efficient development of dispersed reservoirs, making it the "standard technology" in modern oil and gas extraction.

Jianghan Oilfield Fuling Shale Gas Field, Well Jiaoye 44-Z5HF

Set the record for the longest onshore horizontal section in Asia at 5442 meters

Air and Balanced Pressure Drilling: The "Environmental Adaptation Solutions" of Rotary Technology

As "specialized optimized branches" of rotary drilling, these two technologies address complex geology through "adaptation to local conditions."

Air drilling shows unique advantages in arid regions or lost circulation zones—it uses compressed air instead of traditional mud, creating an "aerial conveyor belt" that efficiently carries cuttings back to the surface.

This "water-free operation" mode is highly suitable in the Gobi oilfields of Karamay, Xinjiang. It not only avoids significant mud loss in sandstone layers but also significantly shortens the drilling cycle per well due to continuous cooling of the bit by the air stream.

When encountering moderate loss zones, air mixed with foamers can form a stable foam column, enhancing cuttings transport capacity while reducing formation damage, thus preserving the productivity of vulnerable reservoirs.

Well Bozi 1-2 in the Tarim Oilfield using air drilling technology

Reached a depth of 5068 meters, more than doubling the ROP compared to conventional drilling

Balanced pressure drilling (or managed pressure drilling - MPD) acts like an "underground pressure regulator." When drilling into high-pressure gas zones, barite is added to the mud to "increase weight," providing higher hydrostatic pressure to prevent blowouts. When drilling into low-pressure loss zones, nitrogen can be injected to "reduce weight," lowering the pressure on the formation. It is key for safe operations in deepwater and ultra-deep wells.

II. Deep Earth, Intelligence, Greenness: Industry Trends and Beiken's "Innovative Practices"

Currently, drilling technology is undergoing a profound transformation from "experience-driven" to "data-driven," and from "single-point breakthroughs" to "system integration," forming core trends focused on going deeper, smarter, and greener. Beiken Energy consistently anchors itself in "in-depth domain expertise and continuous innovation," keeping pace with the industry's advancement.

Earlier this year, China's first over-ten-thousand-meter scientific exploration well, "Deep Earth Tako 1 Well," was successfully completed at 10,910 meters, setting the record for the deepest vertical onshore well in Asia and the second deepest globally. The 12,000-meter automated rig used signifies China's deep earth drilling technology ranking among the global forefront.

China's first over-ten-thousand-meter scientific exploration well – Deep Earth Tako 1 Well

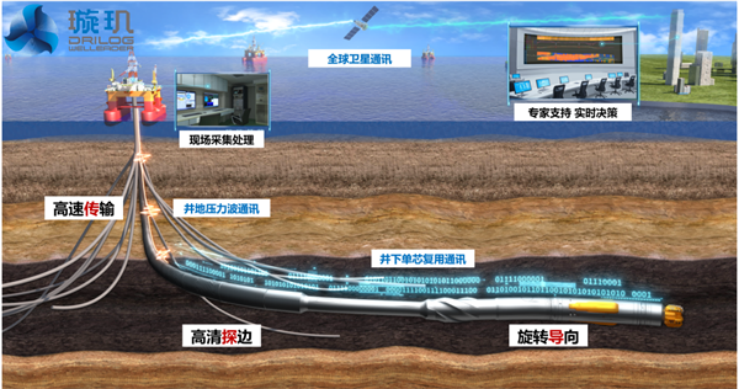

Simultaneously, China's rotary steerable system (RSS) technology has also made breakthrough progress. In July 2025, the China-developed "Xuanji" RSS set records with a completed well depth of 6018 meters, a bottomhole temperature of 158°C, and a single-run footage of 2038 meters, marking China's entry into the ultra-deep well domain with its independent RSS technology. To date, the "Xuanji" system has been deployed on 2751 wells cumulatively, with total footage exceeding 2.6 million meters, and a single-run success rate of 95%.

"Xuanji" System Overall Architecture

Under the "Dual Carbon" goals (carbon peak, carbon neutrality), green drilling technologies with low pollution and low energy consumption have become industry consensus. Beiken Energy is also committed to providing greener and lower-carbon oil and gas development services. In recent years, the company has innovatively used natural gas power generation, among other methods, instead of traditional diesel generators at operational sites to power drilling, fracturing, and other construction operations.

Compared to diesel generation, natural gas power generation has lower carbon emissions, particulate matter, nitrogen oxides, and sulfur oxides, making it more environmentally friendly. It can even utilize wellhead gas directly for power generation after treatment, enabling local consumption of associated gas.

Conclusion:

From the bamboo cables and iron bits of the Shenhai Well to the intelligent rigs of the Deep Earth Tako 1 Well; from the "underground navigation" of directional drilling to the block records continuously set by Beiken Energy—each breakthrough in drilling technology materializes the industry value of "in-depth domain expertise and continuous innovation."

When our drill bits strike the ten-thousand-meter strata, it is not merely a collision of metal and rock, but also a testament to Beiken Energy's resolution to resonate with the industry's frequency. On the Long March of deep earth exploration, Beiken Energy will always hold technology as its torch, persistently tapping into the infinite possibilities of the Earth's depths, moving towards higher efficiency, greater precision, and cleaner operations.

Popular Recruitment

Popular Recruitment

Unlimited, Beijing, Chengdu is better

Unlimited, Beijing, Chengdu is better